With an eye on the long-term business viability, the farming operation at Beckside Farm, near Millom, Cumbria, has invested heavily in a new 350-cow capacity housing facility and 54-point rotary milking parlour.

Primarily to make way for herd expansion plans, the recent investment has provided the infrastructure for what was a 250-head pedigree Holstein herd to increase to 400-head by the end of this year.

But it was not a decision taken lightly, says Patrick Morris-Eyton, who says having a succession plan in place was crucial to it getting the go-ahead.

Patrick spent time working in New Zealand, as well as 18 months doing an apprenticeship on a sheep farm near Crieff, before returning home in 2012 to farm in partnership with his parents, Robert and Rowena, and grandmother Jane. The family have farmed Beckside for some 300 years.

Run over 263 hectares (650 acres) plus hill grazing rights, other elements of the business include an 800-ewe flock of Swaledales, Cheviots and Highlander crosses and a hydro-power and groundwork construction business, with Robert also working as a qualified land agent.

Patrick says: "In 2016, I got more involved with the dairy side of the business. I like numbers and data and thought we could do more to improve that side of the business.

"I wanted to expand our farming operation, and we viewed the dairy enterprise to be the most resilient of the two livestock businesses we run."

Weighing up the options provided the opportunity to step back and look at existing infrastructure and several ideas were tabled, including robots, rapid exit and rotary milking systems.

Patrick says: "Our old parlour was 25 years old and starting to struggle. It was taking more than three hours each end of the day to milk the 210 cows which were going through at the time.

"The existing sheds, built in the 1960s, were also holding us back and, despite being updated, lacked the right light and ventilation.

"We could have expanded the parlour, but there seemed little point given its age, and the existing sheds would not have easily accommodated the number of robots we would have needed to achieve the herd growth we were looking for."

After agreeing dairy expansion was the way to go, extensive market research, involving numerous visits to other dairy units and discussions, took place and the farm sold its lowland flock of 400 sheep to make way for more cows and free up more land for cropping.

Once it started, work progressed rapidly to see two new buildings erected over six months on a greenfield site on the farm a short distance from the existing sheds, which are now being used to house dry cows and youngstock, and the new unit became operational in September last year.

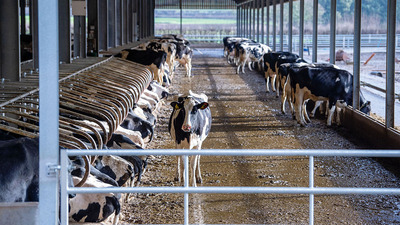

The new parlour, collecting yard and handling facilities are in one building, opposite the new open-sided, housing facility.

A new 27.3 million-litre capacity clay-lined slurry lagoon has also been constructed, as the old system would not have been capable of handling the increased volume.

Feed passages are on both sides of the building, protected from the weather by a 2.5-metre overhang, and with the prevailing wind coming from the west, the need for curtains at the sides of the building was not felt necessary for now.

There are no roof lights to minimise the greenhouse effect, and the building is fitted with an LED lighting system, on for 16 hours/day and controlled by a light sensor.

Two rows of head-to-head cubicles sit between three main and three cross passageways; the outside two at 5m-wide and the inside one 4.5m-wide.

The building is on a 2 per cent gradient, with scraping out at each milking done with a telehandler-mounted scraper, which is favoured over automatic scrapers.

Patrick says: "The bow wave of slurry build-up you get with automatic scraper systems promotes problems such as digital dermatitis, so we wanted to move away from that risk, as well as that of cows knocking their hocks on auto-scrapers."

Wilson C50 head-to-head cubicles are fitted, as is in the existing sheds, but with the addition of 40mm polyurethane foam mats instead of the previously used 30mm design.

Cubicles are bedded twice-daily with sawdust using a Bobman and, although sand was considered, it was ruled out as being incompatible with the gravity-fed slurry system.

Cows also go through an automatic footbath containing a 1 per cent formalin solution after every milking.

Up there with cow comfort and welfare is efficiency, and Patrick says time and cost savings were factored into decisions about design to make sure the system would perform as well as possible for the farm.

He says: "The Bobman has reduced our sawdust usage unbelievably. Without even taking labour saving into account, we are using 50 per cent less sawdust bedding twice-daily than we were bedding up twice/week on 100 more cows."

Another example highlighted was the decision to go with a 5m scraper instead of a 4.5m model, which Patrick worked out would save the operator 18 minutes per day, or 109 hours per year, in scraping time.

When it came to the parlour, the Morris-Eytons settled on a 54-point Waikato rotary system and, with herd expansion on track, target average annual yield per cow is 12,000 litres at 4.06 per cent butterfat and 3.21 per cent protein.

Farm facts

- 263-hectare (650-acre) unit, plus hill grazing rights, rising from 120ft to 1,800ft at its highest point

- 250-cow pedigree Holstein herd set to increase to 400-head by the end of this year

- Recent investment in new 350-cow capacity housing facility and 54-point rotary milking parlour, operational since September last year, to facilitate herd growth

- Target average annual yield per cow is 12,000 litres at 4.06 per cent butterfat and 3.21 per cent protein

- Supplying an Arla Morrisons contract

- Four full-time staff currently employed on-farm, with an additional two working in the farm office, plus family members

- The Morris-Eyton family is holding an open day at Beckside Farm on Tuesday, May 19

The herd has been on three times-a-day milking since the beginning of February, with milk supplied to an Arla Morrisons contract.

Patrick says: "We went for this design because we liked the composite deck on the Centrus platform. It is much lighter than a traditional concrete deck and means there is less wear on the running gear.

"Waikato also had the technology we were looking for, as well as being user-friendly.

"Milking was taking three hours each morning and afternoon in our old 12:24 herringbone parlour, whereas now, one person can milk 200 cows per hour comfortably."

New technology includes electronic milk meters, automatic cluster removal and teat spraying, with teats dry-wiped pre-milking, although pre-spray is also an option.

At 350-head currently, the herd is on track to meet its 400-head target at the end of the year and a major boost to numbers came after the farm purchased 167 cattle of all ages from the dispersal of the Ballyginniff herd in Northern Ireland.

Patrick says: "We are a closed herd and have been for 30 years before purchasing the Ballyginniff herd of cows, but we decided it was not worth having the shed half empty for the time it would have taken us to build up using only our own replacements.

"We were thrilled with the opportunity to purchase such a number of quality animals from this high yielding and high health status herd, and the cows have fitted into our system well."

As well as herd growth, Patrick explains that a lot of consideration was given to herdsman comfort and welfare during the new set-up's design phase.

When advertising for evening milkers recently, he says finding staff was not an issue.

"If you are willing to pay and look after people, finding good labour is not a problem. Our view is that it is as much about looking after people as it is the animals. If you do not have them, you do not have a business."

The existing sheds are being used to house dry cows and youngstock.