In theory, there is enough feed value in one hectare of fresh forage maize to support about 30,000 litres* of milk production, says Dr Mark Leggett; the key is to minimise how much of this is lost when turning it into silage

Carbon dioxide (CO2). We cannot see it, but we hear a lot about it these days, says Volac silage scientist, Dr Mark Leggett. It is a greenhouse gas produced when we burn fuel in our vehicles.

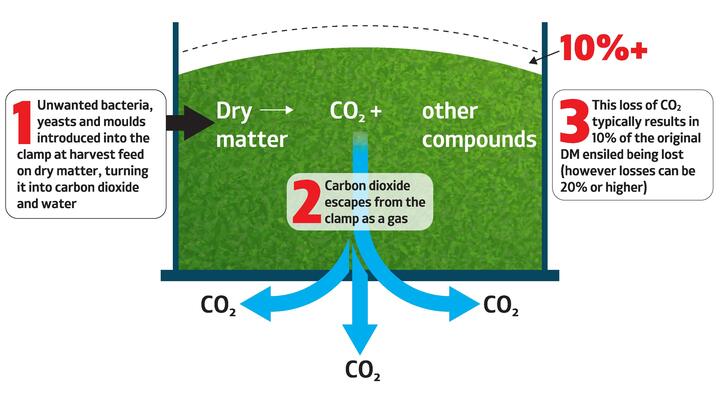

However, in much the same way that CO2 and other gasses are produced when fuel is burned to release energy to power an engine, so too are they produced when the unwanted microorganisms that are inevitably present on forage when harvested control your silage fermentation, he says. Except in this case, the energy released by the breakdown of dry matter (DM) to CO2 is used by these unwanted microbes to grow in the clamp, he points out.

Dr Leggett says: "The question is, do you want the hard-earned energy in the maize crops you have carefully grown used to produce milk? Or, are you prepared for a significant proportion of it to be wasted by these bad microbes before the silage even reaches the cow?

"Maize plants can be high in unwanted microbes – bacteria, yeasts and moulds – for example on dying leaves and on rotting tassels that collect in leaf joints. These microbes are ready to start turning DM into CO2 as soon as the crop is harvested. So tackling them quickly is key."

* Assuming animal maintenance needs have already been met

Stolen energy

Typically, losses in maize silage caused by these unwanted microbes can be equivalent to 1 in every 10 trailer loads of DM originally ensiled, or 2 out of every 10 trailer loads if management is poor, which could include not using an additive, says Dr Leggett. Where spoilage occurs around the vulnerable top and shoulders of clamps, half the DM in these areas can go to waste, he points out.

He says: "What is crucial to realise is that these unwanted microbes feed on sugars and starches first. So the DM that remains in the clamp will be of lower feed value, and therefore less able to support milk production.

"Theoretically, there is enough energy in one hectare of fresh forage maize, before ensiling, to support the production of maybe 30,000 litres of milk, assuming animal maintenance needs have already been met.

"Even if just 10% of that is lost in the clamp, that is 3,000 litres of lost milk production for each hectare of maize grown (1,200 litres/acre). If 20% is lost, that is 6,000 litres/ha (2,400 litres/acre).

"If maize costs you about £1,730/ha (£700/acre) to produce, assuming a yield of 42 t/ha (17 t/acre) treating with a quality additive would only work out at a few percent of that cost. So it is minimal. Yet it puts you in much better control of how well the silage turns out."

What type of additive to use?

When harvesting maize, for the best protection, Dr Leggett advocates using a dual-acting additive. This is because maize can suffer from two types of DM losses, he explains – one type is caused when the unwanted microbes on the crop at harvest are active during the silage fermentation in the absence of air; and the other type occurs when air is present, often during feed-out.

Dr Leggett says: "In both cases, CO2 is produced as these unwanted microbes consume DM. The difference is, it is obvious when yeasts and moulds are feeding on DM once the clamp is opened, because the silage heats up in a process called aerobic spoilage.

"However, more subtle DM losses occur due to the unwanted bacteria. These ferment maize but do so inefficiently. And, because this process does not cause significant heating, and the CO2 produced cannot be seen, you do not know these losses are occurring.

"By applying an additive containing only good bacteria specially selected to carry out an efficient fermentation, such as Lactobacillus plantarum MTD/1, which is the bacterium in Ecosyl and Ecocool additives, you stack the odds in your favour for a better preservation.

"Unlike bad bacteria, Lactobacillus plantarum MTD/1 does not convert sugar to CO2. Instead it converts it only to lactic acid. This has two key benefits. Firstly, lactic acid is excellent at preserving forage against the growth of the unwanted bacteria. Secondly, in the conversion of sugar to lactic acid there is no loss in DM and no production of CO2.

Ecocool

"While Ecosyl contains only Lactobacillus plantarum MTD/1, in Ecocool, MTD/1 is combined with a second beneficial bacterium, called Lactobacillus buchneri PJB/1, hence its dual-acting effects."

Lactobacillus buchneri PJB/1 is highly relevant for maize, says Dr Leggett, because it produces controlled amounts of acetic acid. This inhibits the unwanted yeasts that start the process of silage heating when it is exposed to air, he says, and which in turn can allow moulds to start growing.

He says: "Moulds are important to prevent because not only do they further reduce silage nutritional value, but also silage palatability and moulds also cause mycotoxins.

"You can see Ecocool working because in trials it has been shown to keep silage cool and stable on exposure to air for more than 10 days. It has also been shown to reduce yeast levels by 99.999%.

"Of course an additive is only one part of effective maize conservation, but it is nevertheless an important way of protecting the significant investment that has gone into growing the crop.

"With the drive to farm sustainably and keep on top of bought-in feed costs, minimising DM and nutrient lsses and wastage when making maize silage is key."

How dry matter losses occur in maize silage

How Ecocool additive achieves dual-acting maize silage preservation

Ecocool applies two strains of specially selected beneficial bacteria:

|

Lactobacillus plantarum (MTD/1) To produce an efficient, rapid fermentation |

Lactobacillus buchneri PJB/1 To target yeast and mould growth and so reduce heating and spoilage |

Interested in using a silage additive yourself?

For more information on Volac's Cut to Clamp initiative for better silage, click the link below.

This post is funded by Volac.