With spray jobs stacking up and multiple mixes on the cards, combined with challenging mixing conditions, it's a potential recipe for disaster, cautions Stuart Sutherland, technical manager at Interagro.

Tank-mixing chemicals gives flexibility, saves time, and may increase pesticide effectiveness, but it can also be a sprayer operator's worst nightmare when things go wrong. "An incompatible mix can cause antagonism, reduce efficacy in the field, and cost you a lot of extra time and money when things go wrong," says Stuart.

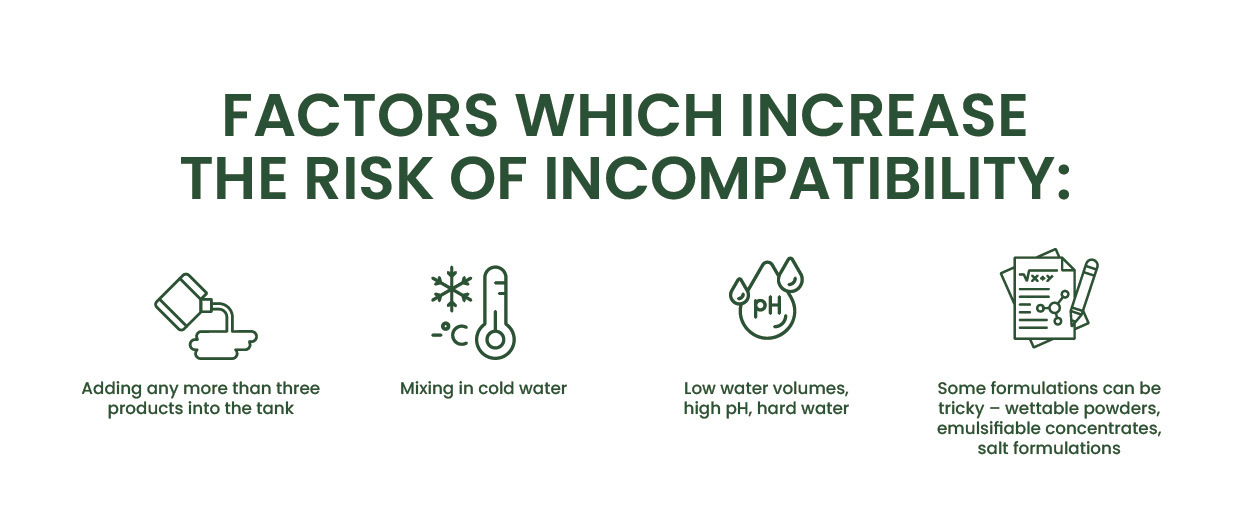

Factors which increase the risk of product incompatibility

"Mixing conditions could be particularly tricky this spring with lots of different products being incorporated together at T1 – and T2 at this rate – to save time.

"Certain pesticides or agrochemicals may not mix well together, leading to issues such as chemical reactions, precipitation, or reduced efficacy – some formulation types such as wettable powders, emulsifiable concentrates and salt formations can be tricky," continues Stuart.

"Cold water, high pH, hard water, all make the mixing process more challenging, and adding any more than three products into the tank increases the risk of incompatibility."

"With spray jobs backing up, there may also be the temptation to reduce water volumes, which will increase the risk of a mixing problem," warns Stuart.

Incorporate a compatibility adjuvant to help overcome mixing challenges

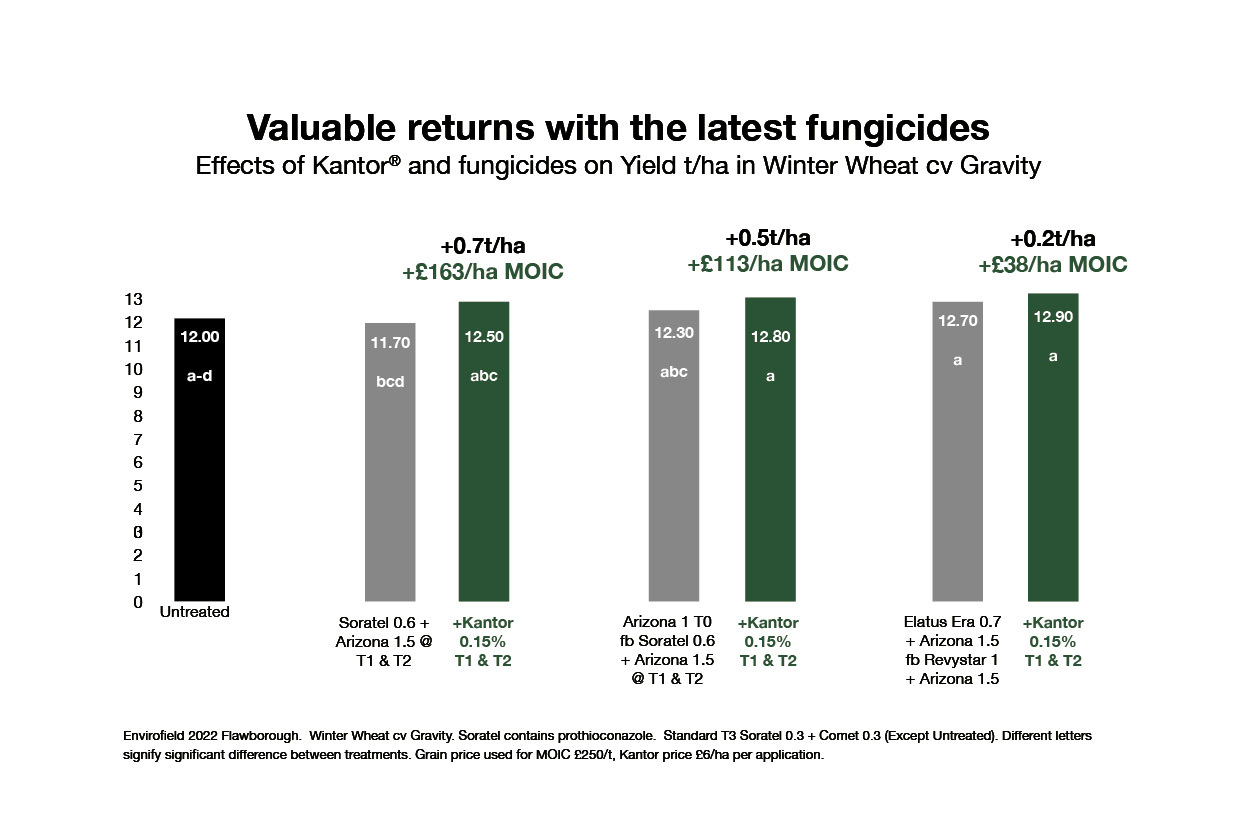

"As well as ensuring products are compatible and best practice filling guidance is followed, incorporating a compatibility adjuvant, such as Interagro's adjuvant Kantor can help to overcome mixing challenges," says Stuart.

Tank-mix compatibility adjuvants can be added to the tank mixture to improve the compatibility of the different products.

"These adjuvants typically work by modifying the physical and chemical properties of the tank mixture, ensuring that the various components remain stable and well-dispersed throughout the spraying process.

"The use of tank-mix compatibility adjuvants can help prevent problems such as clogging of spray nozzles, uneven application of pesticides, or reduced effectiveness of the individual products. They are an important tool for farmers and spray operators to maximise the efficiency and efficacy of their spray applications while minimising potential risks and issues."

Kantor enables complex mixing in a single pass

Extensive testing over the years shows adding Kantor to the spray tank before adding chemicals, speeds up the mixing process and helps traditionally incompatible mixtures to blend together.

"Kantor's unique adjuvant properties promote emulsification, enabling complex tank-mixing in a single pass.

"What's more Kantor helps speed up the process in cold water and will keep products in suspension," adds Stuart. It also contains a pH buffer to protect active ingredients from breakdown if spray water is on the alkaline side.

Watch the video demonstration below showing Kantor improve micronutrient mixing.

Follow best practice tank filling guidance

It's crucial sprayer operators follow best practice filling guidance to minimise the risk of a problem, says Stuart. "The first and vital step, is to start with a scrupulously clean sprayer, even if the sprayer has been sat in the shed over winter. It's really important to flush the tank and lines before kicking off the season, and between spray jobs, just in case there's any unwanted residues from previous mixes that could impact the mixing process."

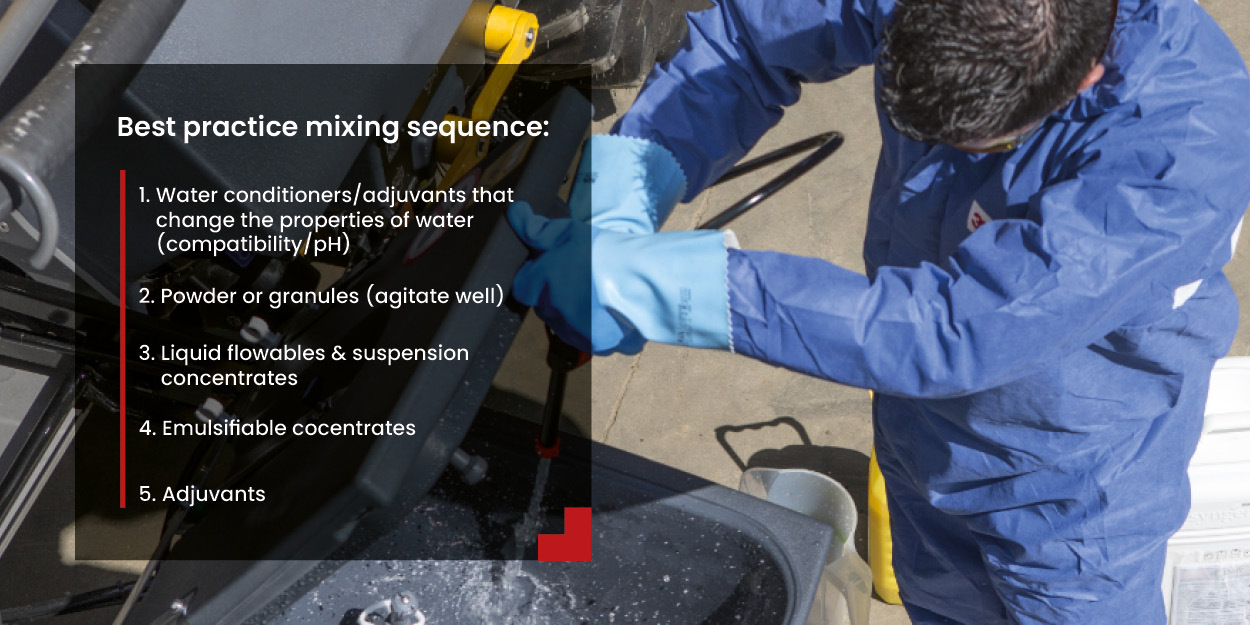

Tank-filling steps to mitigate the risk of a tank-mixing problem:

-

Half fill the spray tank with water before adding any products.

-

Maintain good agitation throughout the filling process.

-

Formulation plays an important part - using the correct mixing order for formulation types is crucial.

-

ALWAYS read product labels & follow guidance.

-

Jar test if unsure of compatibility.

-

Given the risks this season in particular, adding compatibility adjuvant to the water, before adding inputs, is highly recommended to help avoid any problems. Once you've half-filled the sprayer with water, simply add at a rate of 0.15% of the final intended spray volume.

-

Then you can start adding your crop inputs one by one.

-

Add more water as products are added.

-

Make sure concentrates do not come in to contact with each other in the induction bowl.

-

Allow one product to completely clear the induction bowl before adding the next one.

-

Check slow to dissolve formulations like wettable powders and water dispersible granules are in solution before adding more.

-

Only mix up what you need – never leave a mixed solution in the spray tank overnight.

-

Clean the sprayer thoroughly between jobs.

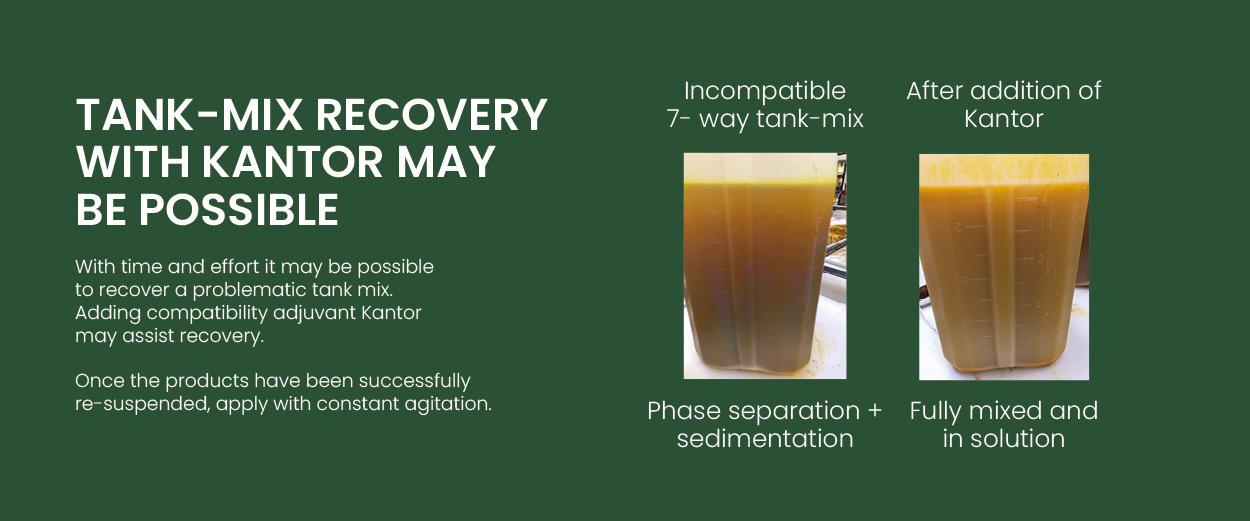

Whilst every effort should be made to avoid a tank-mixing problem, issues can arise, especially in a difficult season. If this does happen, you may be able to lean on Kantor to help recover the mix.

In 2023, a complex 7-way tank-mix application to asparagus proved problematic for Evesham Vale Growers spray operations manager, Will Parrott.

Settling and sedimentation in the spray tank was leaving sprayer nozzles almost completely blocked and Will and his team spent half a day unblocking the spray nozzles and lines.

By adding Kantor, Will was able to recover his mix and apply to the crop with no further issues.

Incorporating Kantor will benefit the efficacy of all products in your tank

Based on the unique, patented class of adjuvant chemistry – the alkoxylated triglycerides – Kantor offers the broadest range of benefits of any adjuvant on the market. Uniquely versatile, adding Kantor to your spray mixture gives you the flexibility to enhance the performance of all products in your tank– post-emergence herbicides, fungicides, insecticides, PGRs, and nutrition.

This is achieved by:

- Promoting emulsification, improving compatibility

- Buffering pH, preventing alkaline hydrolysis

- Reducing spray drift and improving rainfastness, buying you time

- Improving spreading and adhesion, enhancing coverage on target plants

- Unique penetrating power gets active ingredients working faster

For more information on Kantor please visit:

For technical support, call Stuart Sutherland on 07384 460352.